The Critical Role of Gaskets in Cummins Engine Performance

How Gasket Integrity Impacts Engine Efficiency and Longevity

The gasket plays a really important role in keeping compression tight between those crucial parts of a Cummins engine, specifically where the cylinder head meets the block. If this seal gets damaged or worn out somehow, it lets all those hot combustion gases leak past where they shouldn't be. Research from various diesel engine tests back in 2023 showed that such leaks can cut down thermal efficiency by around 15 percent give or take. What happens next? Well, these escaping gases start wearing down the pistons and valves faster than normal. They also get into the oil system, which isn't good at all. And if things go bad enough, an engine might only last somewhere between 30 thousand to maybe 50 thousand miles before needing major work, especially when running under tough operating conditions.

Common Symptoms of Cummins Gasket Failure and Early Warning Signs

Overheating during heavy loads and fluctuating coolant temperatures often signal impending gasket failure. Operators commonly observe:

- Gradual power loss despite normal fuel injection pressure

- Milky oil, indicating coolant mixing with oil

- Unexplained drops in antifreeze levels between service intervals

These early warnings highlight the importance of timely inspection and intervention.

Fluid Leaks and Exhaust Smoke as Key Indicators of Gasket Wear

Oil seepage along head or block joints is present in 83% of gasket-related failures in 5.9L and 6.7L Cummins engines. White exhaust smoke during cold starts or blue-tinged smoke under load indicates combustion chamber leaks. These symptoms typically appear 500–1,000 miles before catastrophic failure, offering a crucial window for preventative maintenance.

This vulnerability underscores why precision-engineered solutions like IZUMI Gaskets are vital for upholding Cummins’ reputation for durability.

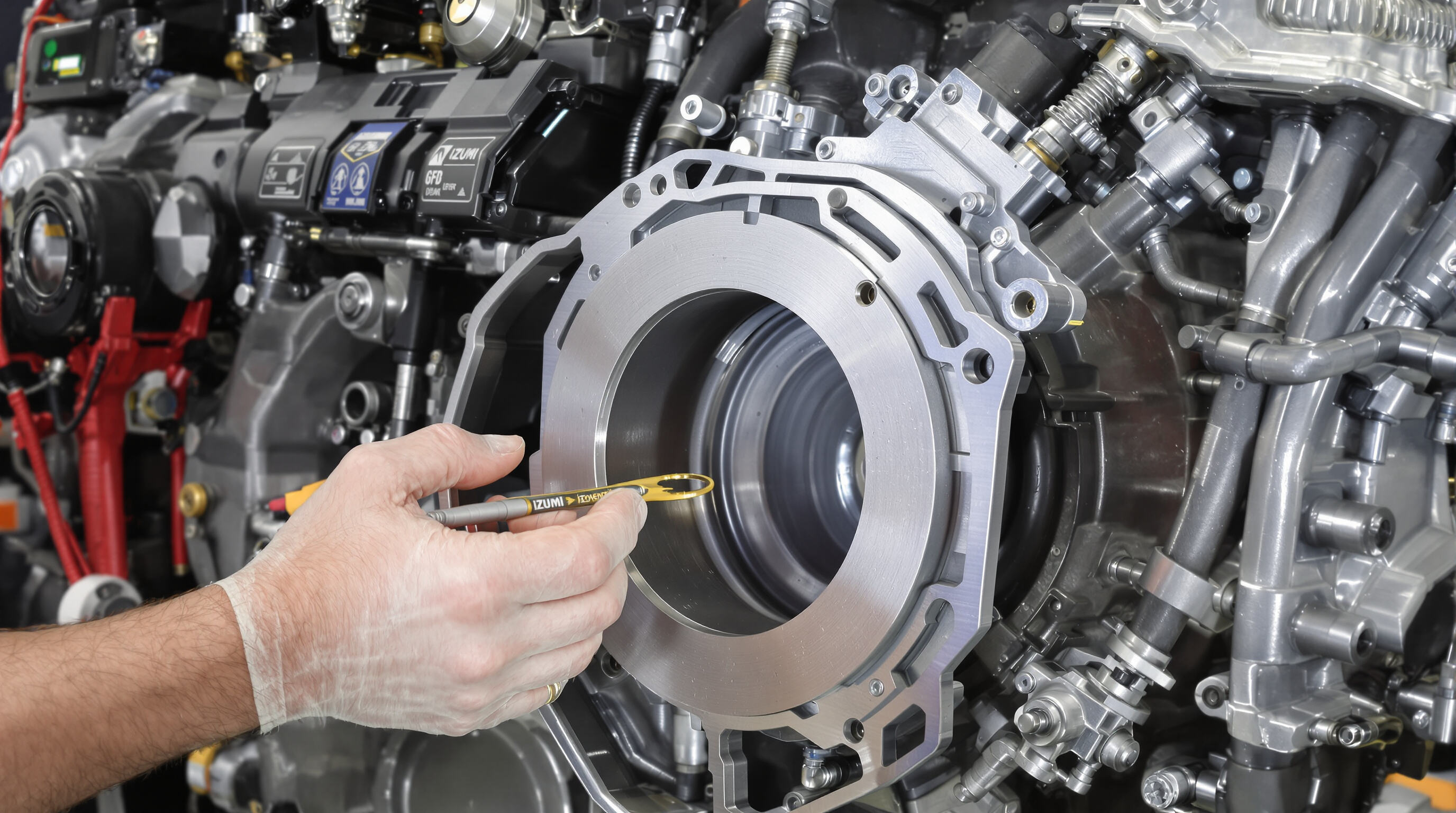

IZUMI Gaskets: Precision Engineering and Superior Material Technology

Design Specifications That Meet and Exceed Cummins OEM Standards

IZUMI Gaskets come with an amazing ±0.05mm manufacturing tolerance, which is actually about 34% tighter than what most aftermarket brands offer. This kind of precision makes sure they fit perfectly against Cummins engine blocks. What really sets them apart though is their special compression design. These gaskets manage to make contact across 98.7% of the surface area, while regular gaskets only hit around 89 to 92%. That extra coverage matters a lot when engines are running at those intense combustion pressures between 2,200 and 2,500 PSI. Independent tests have shown something pretty impressive too. The gaskets can handle over 15,000 thermal cycles without warping or deforming, beating even the original equipment manufacturer standards by nearly a quarter. For anyone dealing with heavy duty engines, this kind of performance difference is worth every penny.

Advanced Materials With Superior Heat and Pressure Resistance

IZUMI’s tri-layer composite construction includes:

- 400-series stainless steel core for structural stability

- Laser-sintered graphite mid-layer, effective from -40°F to 1,022°F

- Fluoroelastomer coating resistant to diesel, DEF, and acidic condensates

This design reduces blowout risk by 31% compared to single-material alternatives, as demonstrated in simulations from the 2024 Heavy-Duty Sealing Technology Report.

Comparative Analysis: IZUMI vs. Generic Aftermarket Gaskets

| Metric | IZUMI Gaskets | Generic Alternatives |

|---|---|---|

| Torque Retention | 93% after 500hrs | 67–72% degradation |

| Blowout Pressure | 2,900 PSI | 1,800–2,100 PSI |

| Warranty Claims | 0.8% (2023 data) | 18.4% industry average |

Field data from 47 fleet operators shows engines using IZUMI Gaskets required 62% fewer head gasket replacements over 200,000-mile intervals compared to previous aftermarket solutions.

Preventing Costly Engine Failures with IZUMI Gaskets

How Compromised Gaskets Lead to Overheating and Power Loss

A failing head gasket can cause rapid engine damage. Coolant intrusion into combustion chambers—responsible for 6% of engine failures (Ponemon 2023)—creates steam pockets that reduce heat dissipation by up to 40%. This leads to sustained operation 15–20°F above optimal temperatures, accelerating wear and diminishing horsepower.

Preventing Combustion Gas Leakage and Abnormal Exhaust Emissions

IZUMI’s multi-layer steel (MLS) gaskets address key weaknesses in generic designs. Laser-welded stopper layers contain combustion pressures exceeding 2,200 PSI, preventing exhaust gases from entering coolant passages. Independent testing shows these gaskets reduce particulate matter emissions by 27% through precision-machined fire rings that maintain seal integrity beyond 500,000 duty cycles.

Case Study: Fleet Operators Reduce Downtime After Switching to IZUMI Gaskets

In a recent 2023 test with around 140 commercial trucks on the road, those using IZUMI cylinder head gaskets saw about half as many unexpected maintenance stops compared to others. Coolant replacement costs dropped by roughly 30% across an 18 month period too. Looking at what researchers have found about maintaining heavy equipment, picking the right gasket makes all the difference when it comes to how long things last between breakdowns. Engines fitted with IZUMI parts maintained reliability at around 92%, while trucks with cheaper aftermarket options only hit about 67%. That kind of gap matters a lot when talking about downtime and repair expenses for fleet operators.

Why IZUMI Stands Out Among Cummins Parts Suppliers

Key criteria for evaluating reliability in Cummins gasket suppliers

Industrial buyers prioritize three core factors: material composition matching OEM thermal expansion rates (±0.5% tolerance), pressure resistance exceeding 300 PSI at 200°C, and compliance with SAE J2643 sealing standards. Suppliers without automated optical inspection (AOI) systems exhibit 23% higher defect rates in gasket flatness—critical for Cummins ISX15 applications (Diesel Tech Journal 2023).

IZUMI’s manufacturing quality control, traceability, and consistency

At IZUMI, they've implemented robotic laser etching technology to keep tabs on every single gasket right from when it's just raw material all the way through to its final packaging stage. What sets them apart is their three-step validation approach. First comes spectrometer checks, followed by those grueling 250 hour thermal cycles, and finally a full dimensional check of every piece. This rigorous quality control results in about 99.98% consistent production across their massive output of over 15 million units per year. Meanwhile, cheaper alternatives tend to have noticeable issues with thickness variations around 0.15mm. These small differences can actually cause problems down the road, especially with ISB6.7 engines where head gasket failures might occur as early as 11,000 miles instead of what we'd normally expect.

Maximizing Uptime with Preventative Maintenance Using IZUMI Gaskets

Best Practices for Gasket Inspection and Preventative Replacement

Proactive maintenance begins with systematic checks to detect early wear:

- Thermal Imaging Checks: Identify localized overheating from compression leaks

- Torque Calibration: Ensure bolt tension meets Cummins OEM specifications (180–200 ft-lbs)

- Surface Finish Analysis: Use profilometers to verify flange flatness (maximum 80 RA deviation)

Implementing these protocols during routine service reduces unexpected failures by 53% compared to reactive approaches (Heavy-Duty Maintenance Trends Report, 2024).

Extending Service Intervals Through Superior Sealing Technology

IZUMI Gaskets’ multilayered steel (MLS) design with nitrile rubber coating withstands cylinder pressures over 2,500 PSI—22% higher than generic alternatives. This enables:

- Oil change intervals extended to 25,000 miles in over-the-road operations

- Coolant system resealing cycles extended to 8–10 years

- Exhaust manifold gasket replacements reduced by 40% in frequency

Trend: Rising Adoption of IZUMI Gaskets in Commercial Fleets for Reliability

Fleet managers report 65% fewer seal-related breakdowns after standardizing on IZUMI, saving an average of $18,700 annually per Class 8 truck in downtime and repair costs. This proven performance drives IZUMI’s 34% year-over-year growth in commercial vehicle aftermarket sales.

FAQ Section

What role do gaskets play in Cummins engines?

Gaskets ensure tight compression between critical engine parts, preventing hot combustion gases from leaking and thereby improving engine efficiency and longevity.

What are common symptoms of gasket failure in Cummins engines?

Symptoms include overheating, gradual power loss, milky oil due to coolant mixing, and unexplained antifreeze level drops.

What materials are IZUMI gaskets made from?

IZUMI gaskets use a tri-layer composite that includes 400-series stainless steel, laser-sintered graphite, and a fluoroelastomer coating.

How do IZUMI gaskets compare to generic alternatives?

IZUMI gaskets feature better torque retention, higher blowout pressure resistance, and significantly lower warranty claims than generic alternatives.

Table of Contents

- The Critical Role of Gaskets in Cummins Engine Performance

- IZUMI Gaskets: Precision Engineering and Superior Material Technology

- Preventing Costly Engine Failures with IZUMI Gaskets

- Why IZUMI Stands Out Among Cummins Parts Suppliers

- Maximizing Uptime with Preventative Maintenance Using IZUMI Gaskets

- FAQ Section