Understanding Cylinder Liners and Replacement Needs

What Are Cylinder Liners?

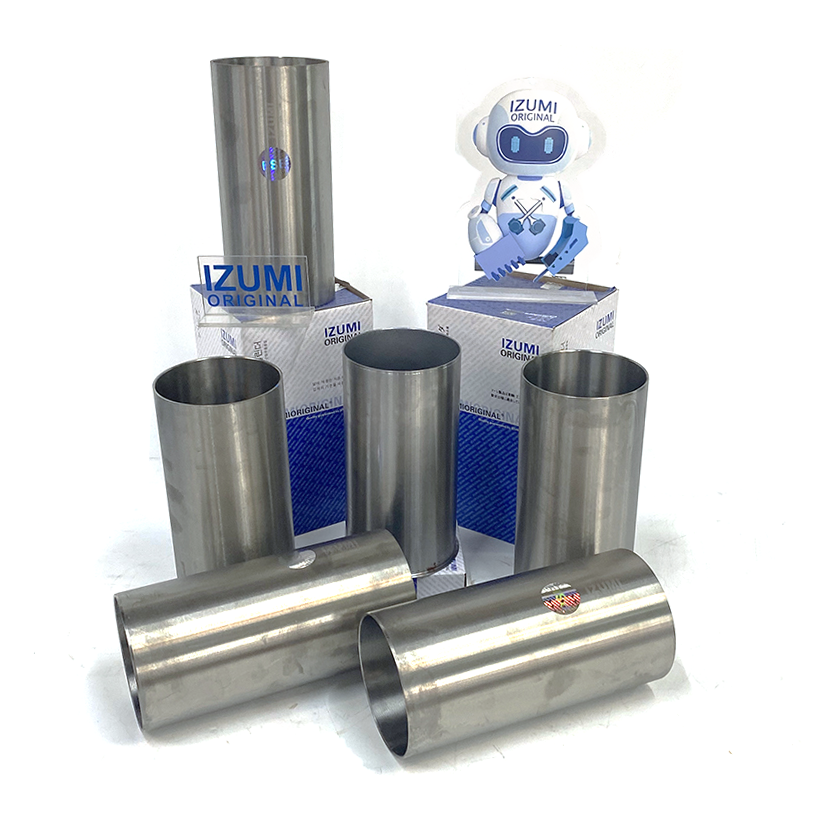

Cylinder liners, or cylinder sleeves, are integral components of an engine that ensure its efficiency and longevity. They form the inner wall of the combustion chamber, providing a smooth, wear-resistant surface for pistons. This crucial function prevents damage to the engine block while maintaining efficient performance. Cylinder liners are primarily made from cast iron and steel. Cast iron is valued in heavy-duty engines for its robustness, while steel liners excel in high-performance scenarios due to their exceptional wear resistance.

In terms of types, there are two main cylinder liners—wet and dry. Wet liners are directly cooled by the engine's coolant and are often used in large, heavy-duty engines. Conversely, dry liners are pressed into the cylinder block and cooled indirectly, favored in lighter or high-revving engines. Choosing the correct type and material is essential for the engine's overall health and efficiency.

Signs Your Liners Need Replacement

Recognizing signs indicating the need for cylinder liner replacement is vital for maintaining optimum engine performance. Common symptoms include excessive oil consumption and deteriorating engine performance, often signifying wear or damage. Additionally, visual markers like scoring or scratches observed during inspections can confirm that liners need attention. Regular diagnostic methods such as compression tests are essential for determining the condition of cylinder liners.

Neglecting these symptoms can have severe repercussions; studies suggest engine efficiency can drop by up to 20% due to neglected cylinder liner maintenance. Therefore, monitoring these indicators and conducting regular check-ups is critical to preventing engine failures and ensuring long-term reliability.

LSI Integration: High-Performance Engine Parts & Longevity

Integrating high-performance engine parts is crucial for enhancing engine longevity and efficiency. High-quality cylinder liners, for instance, are fundamental in sustaining engine performance under harsh conditions, thus reducing wear on associated components like pistons and rings. By using robust materials and coatings, these liners help withstand demanding environments while maintaining functionality.

Expert opinions highlight that by choosing superior components, like high-performance liners, engines can experience less frequent maintenance and longer service intervals. This approach not only boosts operational efficiency but also significantly reduces long-term maintenance costs. Emphasizing the use of durable cylinder liners can profoundly impact vehicle efficiency, making them a wise investment for any engine application.

Essential Tools and Safety Protocols

Specialized Tools for Liner Removal/Installation

Using the right tools is crucial when removing or installing cylinder liners. Key tools include torque wrenches for accurate bolt tension, liner pullers specifically designed for safe liner extraction, and liner installation tools to ensure correct seating. Using improper tools can damage engine components, leading to costly repairs. For quality assurance, I recommend brands like Snap-on, Mac Tools, and Proto, which are well-regarded among professionals for their durability and precision.

Safety Gear and Workspace Best Practices

Safety shouldn't be compromised when dealing with engine maintenance. Essential safety gear includes gloves to protect your hands, goggles to shield your eyes from debris, and protective suits to prevent contaminants from affecting your skin. Maintaining an organized workspace is equally important. Ensure tools are stored systematically to avoid tripping hazards and accidents. According to a report by the Occupational Safety and Health Administration (OSHA), proper safety protocols can reduce workplace accidents by 25%, highlighting the effectiveness of using the right protective gear and maintaining an orderly workspace.

LSI Note: Trusted Suppliers (Yanmar, Cummins, Caterpillar)

Sourcing parts from reputable suppliers like Yanmar, Cummins, and Caterpillar is vital for engine reliability. Trusted suppliers ensure parts that meet rigorous standards, guaranteeing performance. Yanmar, for instance, is known for its innovative engine solutions, and Cummins provides an extensive parts catalog for diverse needs. Meanwhile, Caterpillar excels in high-performance engine parts. To locate these suppliers, explore online directories or consult with local automotive professionals who can guide you to verified sources, ensuring quality and authenticity in your engine components.

Step-by-Step Cylinder Liner Replacement Process

Draining Fluids and Disassembling Components

Commencing the cylinder liner replacement process demands a meticulous approach, starting with safely draining engine fluids. It's vital to completely drain oil, coolant, and fuel to prevent spills and environmental contamination. Once drained, disassembly begins with removing the cylinder head, pistons, and connecting rods. Here's a step-by-step guide:

-

Draining Fluids:

- Ensure all fluids are drained using drip pans to collect them.

- Properly dispose of fluids following environmental guidelines to avoid contamination.

-

Disassembling Components:

- Remove components like the cylinder head, pistons, and connecting rods in order.

- Organize removed parts for quick reassembly and damage prevention.

Practicing caution and following these steps will help maintain engine integrity and prevent costly damage during disassembly.

Dry vs. Wet Liner Removal Techniques

Choosing between dry and wet liner removal techniques depends on the engine type and conditions. Each method has its advantages and challenges:

-

Dry Liner Removal:

- Preferred for liners that don't contact coolant and often requires heating the block.

- Easier to remove with fewer risks to engine components.

-

Wet Liner Removal:

- Requires careful handling due to sealing rings, necessitating greater extraction force.

- Demands meticulous safety protocols to avoid equipment damage.

Though dry liners offer simplicity, wet liner removal requires additional precautions. Expert opinions suggest using quality tools and adhering to safety guidelines for successful execution.

Cleaning and Inspecting the Engine Block

The cleaning and inspection of the engine block are crucial steps in ensuring effective cylinder liner replacement. Here's a detailed guide:

-

Cleaning the Engine Block:

- Remove any debris to prevent impairments during new liner installation.

- Use appropriate cleaning solvents, following manufacturer recommendations.

-

Inspecting the Engine Block:

- Check for cracks, warping, or other signs of damage.

- Address any irregularities found during the inspection, as unresolved issues may necessitate repairs.

Maintaining a clean and damage-free surface is essential for optimal engine performance and longevity. Regular upkeep is indispensable to sustain consistent engine health.

Installing New Liners: Press-Fit Protocols

For successful installation of new cylinder liners, adhering to press-fit protocols is crucial. The installation process involves attention to temperature and lubrication to ensure a proper seal:

-

Preparing for Installation:

- Pre-cool liners and slightly heat the block to facilitate smoother fitting.

- Lubricate the seal area thoroughly, using recommended lubricants.

-

Press-Fit the Liners:

- Utilize hydraulic or torque tools for the press-fit procedure.

- Ensure liners fit tightly to minimize engine failures and improve longevity.

Precision and adherence to OEM guidelines are vital for a flawless installation. Recognizing common mistakes and knowing how to avoid them will bolster performance outcomes significantly.

Post-Installation Testing and Maintenance

Protrusion Measurement and Alignment Checks

Understanding protrusion measurement is vital to ensuring the successful installation of cylinder liners. Protrusion measurement refers to assessing how much the liners extend above the engine block level, playing a crucial role in maintaining engine balance and sealing integrity. To conduct alignment checks, start by measuring each liner’s protrusion using a precision gauge; ensure they fall within specified limits to avoid combustion chamber irregularities. If these checks are overlooked, misalignment can lead to uneven wear, decreased engine efficiency, and potential catastrophic failures, highlighting the importance of this step in the post-installation process.

Break-In Procedures for Optimal Seating

Performing proper break-in procedures is essential for achieving optimal seating of the new cylinder liners, which minimizes wear and maximizes performance. The break-in process involves gradually running the engine under varied loads to gently seat the liners and pistons. During this phase, monitor engine performance for abnormal sounds, leaks, or temperature fluctuations to ensure everything is functioning correctly. Expert advice emphasizes the importance of the break-in period, as inadequate procedures can lead to premature engine damage and compromised liner longevity. Properly executed, these protocols help to secure the liner's position and improve its durability over time.

LSI Tip: Perkins & Mitsubishi Engine-Specific Guidelines

When dealing with Perkins and Mitsubishi engines, specific guidelines need to be followed for cylinder liner maintenance to ensure compatibility and performance. Each engine model may have unique maintenance strategies to cater to its design and operational demands. For instance, Perkins engines might require specific torque settings and seals differing from Mitsubishi models, which necessitates checking the manufacturer's manuals for precise instructions. Resources such as engine-specific manuals or online databases can provide in-depth guidance on handling variations across different models, ensuring the engine maintains its efficiency and reliability through proper maintenance practices. This approach helps tailor your maintenance efforts to the exact specifications of these engines, enhancing their performance.

Sourcing Reliable Replacement Parts

OEM vs. Aftermarket Liners: Key Differences

Understanding the differences between OEM (Original Equipment Manufacturer) liners and aftermarket options is critical when sourcing replacement parts for engines. OEM liners are produced by the original manufacturer, ensuring compatibility and meeting industry standards. They often offer superior performance and reliability, albeit at a higher cost. Conversely, aftermarket liners can be a more economical choice and sometimes provide improved designs. However, they vary in quality, requiring diligent assessment of material and performance specifications to avoid compromising engine functionality. Evaluating industry certifications and comparing performance metrics of these liners helps ensure they meet your requirements for quality and durability.

LSI Focus: Caterpillar Engine Parts Catalog Insights

Navigating the Caterpillar engine parts catalog effectively can significantly streamline the sourcing process for quality parts. The key is familiarizing oneself with the catalog's structure and utilizing search tools and filters to pinpoint the needed items promptly. Reliable parts are often backed by robust documentation and customer testimonials, attesting to their durability and compatibility. Success stories highlight how parts sourced from Caterpillar's catalog have resolved complex repair challenges, underscoring their reliability. Engaging with user reviews and case studies can further aid in reassuring the decision to select Caterpillar parts for stringent engine requirements.

Quality Assurance for Long-Term Performance

Quality assurance processes are absolutely crucial in verifying the durability and effectiveness of cylinder liners over time. These processes typically include rigorous testing methods such as material composition analysis, stress testing, and dimensional verification to ensure long-term performance. Studies consistently show that quality assurance directly impacts the lifespan of parts, with high-quality liners exhibiting longer service intervals and reduced maintenance needs. Implementing thorough checks minimizes unforeseen failures, ensuring the engine operates smoothly and efficiently in demanding conditions. This proactive approach safeguards investments in engine components by promoting steadiness and reliability.