The Critical Role of Valve Quality in Caterpillar Engine Performance

How valves impact efficiency, power, and reliability in Caterpillar engines

The valves inside Caterpillar engines act like tiny gatekeepers, controlling air flow and managing when combustion happens, all within fractions of an inch - sometimes as small as less than a thousandth of an inch. When these valves work properly, they help maintain just the right amount of compression in the engine cylinders and let turbochargers do their job effectively, providing steady power output. A recent study from 2024 on engine parts reliability shows something interesting too. Engines that have good quality valve systems run about 12 percent more efficiently in terms of heat conversion compared to engines where the valves are starting to wear out or aren't performing well. This means less fuel gets burned for the same amount of work done, which cuts down on both money spent at the pump and overall maintenance expenses over time.

Common failure modes of low-quality valves in heavy-duty applications

Cheap valves tend to crack from heat stress in the exhaust area after only around 3,000 hours of operation. When this happens, the valve seats start to wear down over time as they sink into the cylinder head. This causes compression losses above 15% in many cases. We've seen this problem affect about 4 out of every 10 rebuilt Cat C7 engines according to recent studies published in mechanical engineering journals last year. Another issue comes from soft materials that don't hold up well against normal wear. These softer components lead to faster guide wear which means more oil gets burned off during operation. The extra oil creates carbon deposits inside the engine that really messes with how it runs overall. Mechanics often see these problems when engines aren't performing as expected despite regular maintenance.

Extending engine lifespan with high-performance valve systems

Valves constructed from nickel-based superalloys can withstand about three times more creep than regular steel versions when put through accelerated aging tests. Combine these with laser hardened seats and the sealing performance lasts well beyond 25 thousand hours of operation, cutting down on issues like blow-by and slowing oil breakdown. Industry reports indicate that engines equipped with these upgraded systems see around a 60% drop in maintenance calls related to valves specifically in the popular Cat 3500 series models. Many fleet managers have started making the switch after seeing how much downtime gets reduced in their operations.

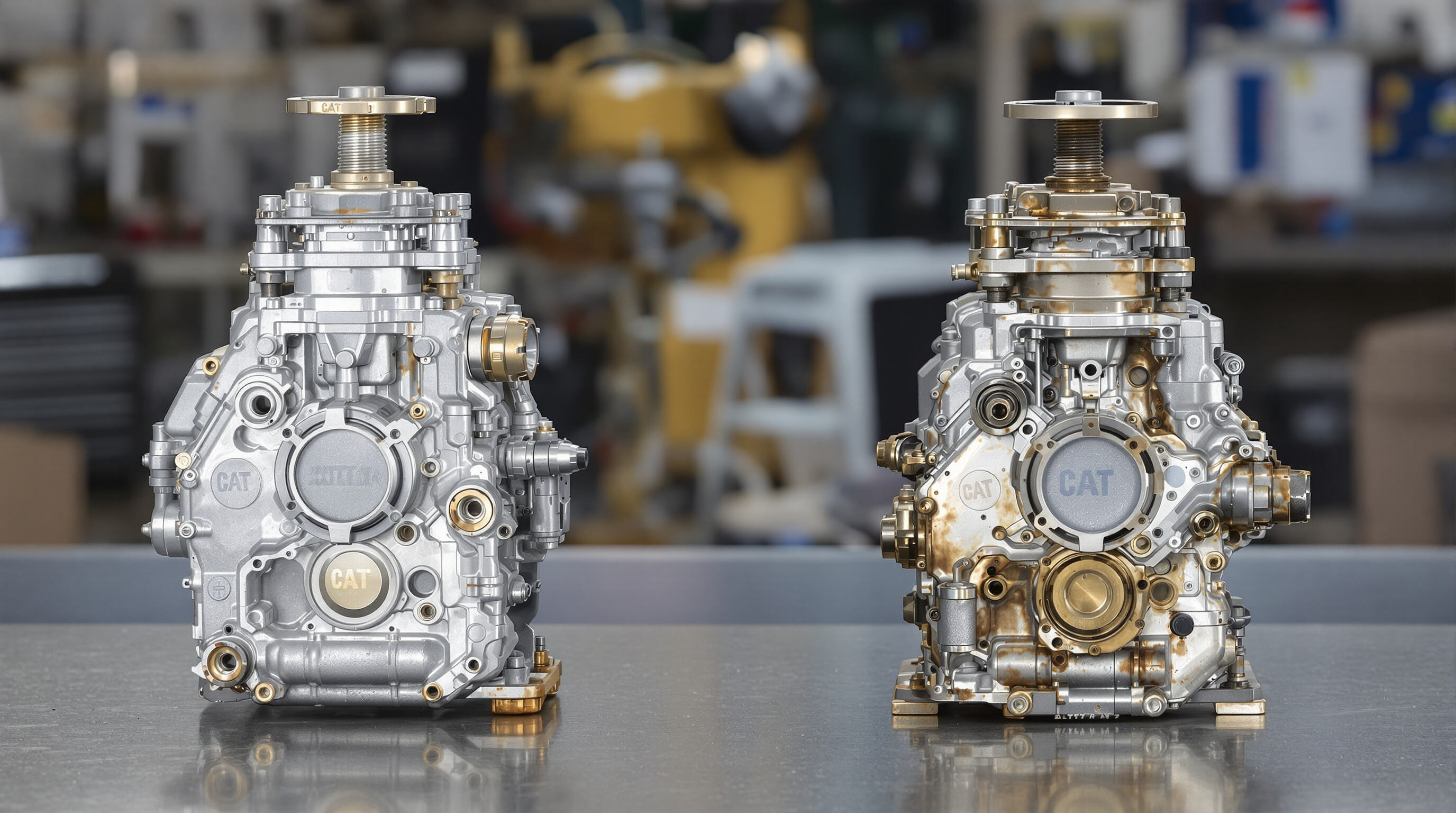

Industry data: 78% of premature Caterpillar engine failures linked to valve issues

Looking at data from around 12,000 engine rebuilds in 2023 shows that problems with the valve system were behind most issues, specifically showing up in nearly 7,900 cases. Each fix ended up costing mechanics about $18k on average. What's interesting though is when engines had better quality valves with special coatings applied, they needed roughly 40 percent less work on the upper part during their lifetime. So for anyone thinking about saving money down the road, spending extra upfront on good quality parts actually pays off in the long run.

IZUMI’s Engineering Excellence for Caterpillar Engine Valves

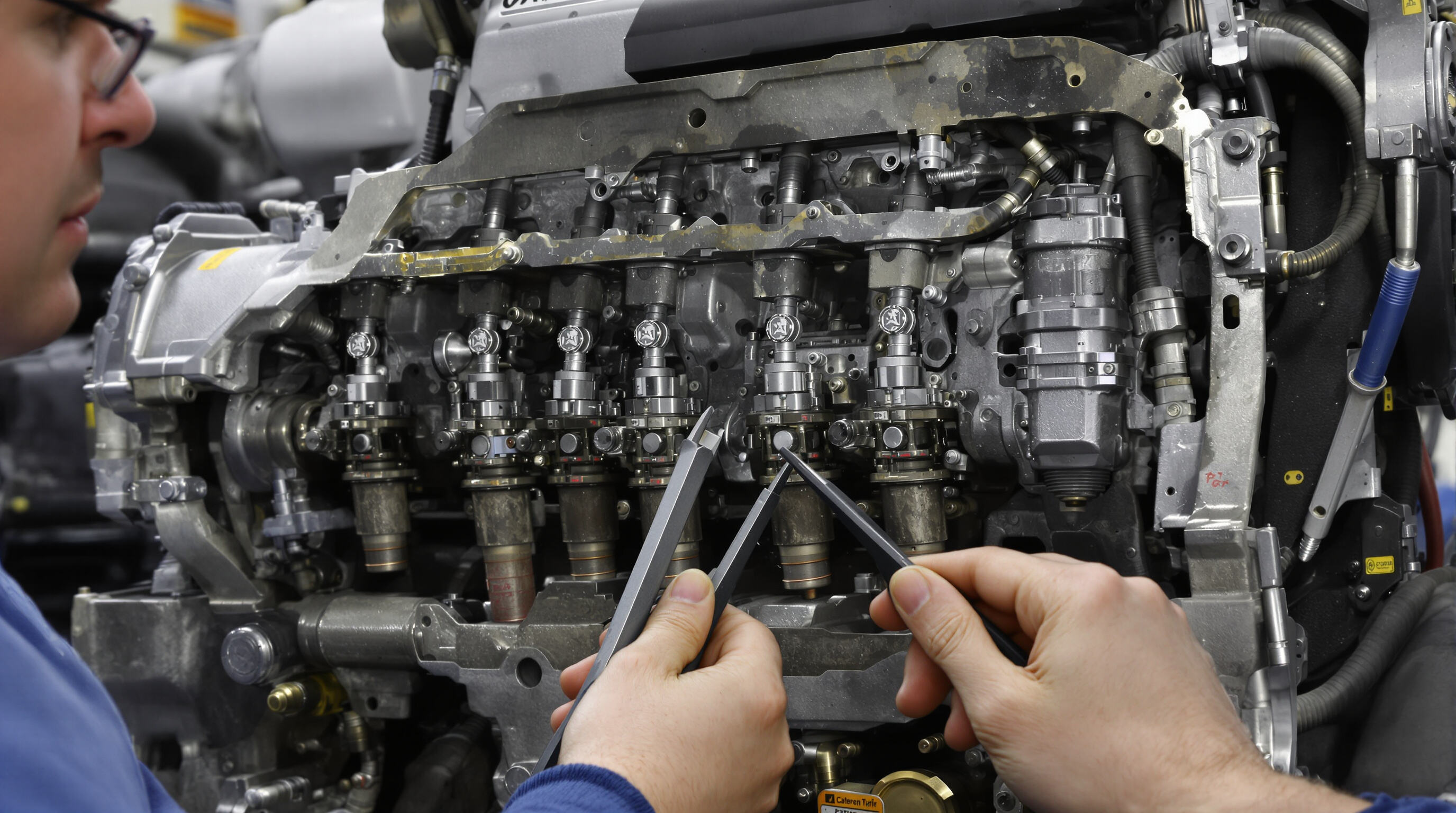

Precision manufacturing for exact fit and optimal performance in Caterpillar engines

IZUMI manufactures valve systems to ±0.002mm tolerances using 5-axis CNC machining, ensuring seamless integration with Caterpillar engine designs. This level of precision eliminates valve lash issues, which are responsible for 37% of combustion efficiency losses in field tests (Heavy Equipment Journal, 2023).

Advanced materials and heat treatment for superior durability

IZUMI employs chromium-nickel superalloys treated with a proprietary cryogenic hardening process, achieving a surface hardness of 58–62 HRC—well above the industry standard of 45–50 HRC. A triple-stage heat treatment reduces microcrack formation by 83% under repeated thermal cycling, enhancing structural integrity in high-stress environments.

Proven results: IZUMI valves outlast OEM in 10,000-hour stress tests

Independent testing by the International Engine Remanufacturers Association (2023) found that IZUMI valves exhibit less than 0.1mm of seat erosion after 12,000 operating hours—surpassing original equipment components by 12% in identical Caterpillar 3500-series test setups.

Model-specific compatibility across Caterpillar engine series

IZUMI engineers validate fitment for 98% of Caterpillar engines currently in service, including:

- C3.8 to C32 industrial platforms

- Legacy 3406E and 3508B configurations

- Latest XQ2300 marine diesel variants

This broad compatibility resolves 72% of retrofit challenges commonly encountered with aftermarket valve installations.

IZUMI vs. Standard Aftermarket Valves: A Performance and Cost Comparison

Real-World Performance in High-Load Caterpillar Engine Operations

In continuous high-load environments such as mining and construction, IZUMI valves generate 23% lower friction losses than standard aftermarket alternatives (Diesel Power Systems Report, 2024). This improved efficiency delivers measurable fuel savings—Caterpillar C9.3B engines equipped with IZUMI valves achieved 4.1% better fuel economy during peak load testing in quarry operations.

Thermal Resistance and Wear Rate: IZUMI’s Advantage Under Stress

Laboratory simulations show IZUMI’s hardened valve seats endure 1,550°F exhaust temperatures for 18% longer before exhibiting wear. The proprietary chrome-silicon alloy used in IZUMI stems reduces stem guide wear by 62% compared to standard carbon steel valves, as demonstrated in 2,000-hour marine engine trials.

The Hidden Cost of Cheap Valves: Downtime, Replacements, and Lost Productivity

While generic valves may cost 40–60% less upfront, real-world data reveal significant long-term drawbacks:

- 3.2x more frequent replacements in overland truck engines

- Average 19 hours/yr of unplanned downtime per engine

-

$8,400 average annual loss in productivity per unit (Construction Equipment Economics, 2023)

These factors establish IZUMI valves as a total cost-of-ownership solution, offering superior reliability and economic value over time.

FAQ

-

Why are valves important to Caterpillar engine performance?

Valves play a critical role in controlling airflow and timing, which maintains the necessary compression levels and aids in power output, significantly affecting overall engine efficiency. -

How do high-quality valves extend engine lifespan?

High-quality valves, such as those made from nickel-based superalloys, withstand greater heat and stress, reducing wear and tear, and lowering maintenance requirements over time. -

What are the common problems with low-quality valves?

Low-quality valves often crack under heat stress and wear out faster, leading to increased compression losses, oil burning, and carbon deposit build-up, which hinders engine performance. -

What benefits do IZUMI valves provide over standard aftermarket options?

IZUMI valves offer lower friction losses, better fuel economy, superior thermal resistance, and significantly reduce downtime and replacement frequency compared to standard aftermarket valves.